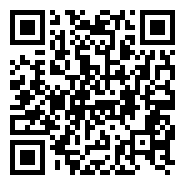

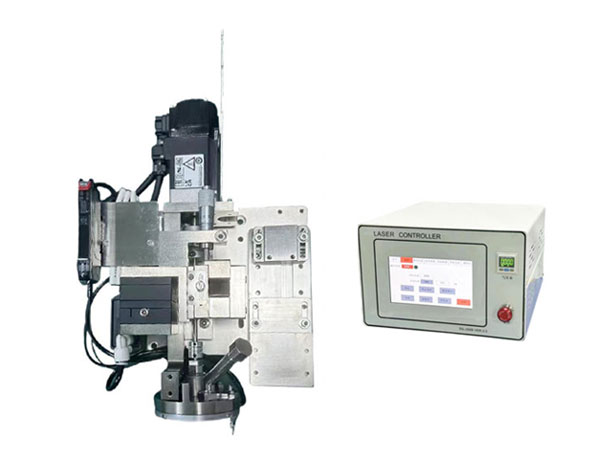

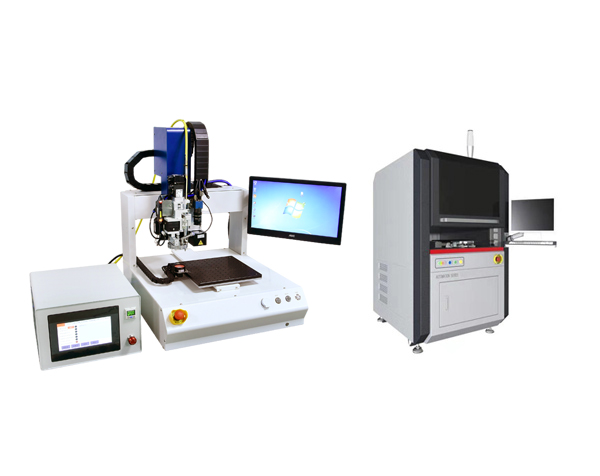

Laser solder ball welding module

This product is a welding module, which can be flexibly installed on the standard platform machine or customized machine to realize the laser tin ball tin spraying process;

It includes the installation of mechanical unit and independent electric control box. The mechanical part is installed on the z-axis mechanism of X-Y-Z platform, and the electrical is connected with the I / O communication of main console;

The control mode is simple. Only a few IO points can complete a series of actions such as ball dropping, laser output, ball spraying and so on.

It includes the installation of mechanical unit and independent electric control box. The mechanical part is installed on the z-axis mechanism of X-Y-Z platform, and the electrical is connected with the I / O communication of main console;

The control mode is simple. Only a few IO points can complete a series of actions such as ball dropping, laser output, ball spraying and so on.

0769-23127991

product features

high performance

- Ball speed --- 8 balls per second

- Superior output --- 7200 points per hour

high precision

- Yield & ndash; More than 99.5%

- The welding accuracy shall be controlled within & plusmn; 5μ Within

- M

high flexibility

- Solder ball selection & ndash; From 100 microns to 1800 microns

- High weld metal & ndash; SnPb, SnAg, SnAgCu, AuSn,

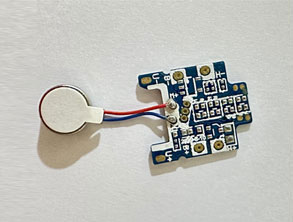

product parameters

| Control mode | PLC control + PC image processing |

| Power | 3KW |

| Power supply | AC220V |

| Special air source | Nitrogen |

| Bond head size | 350*220*105 mm |

| Controller size | 265*398*217 mm |

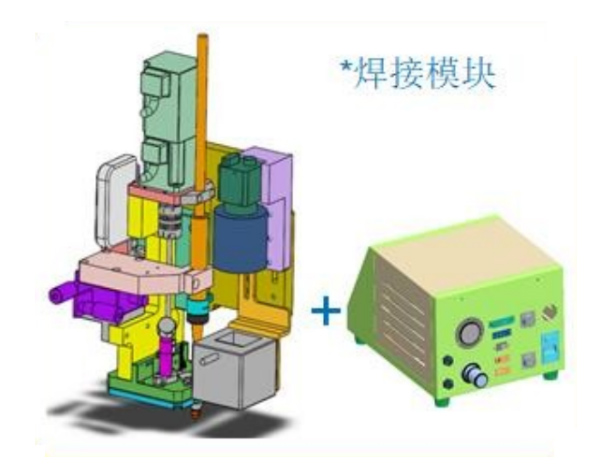

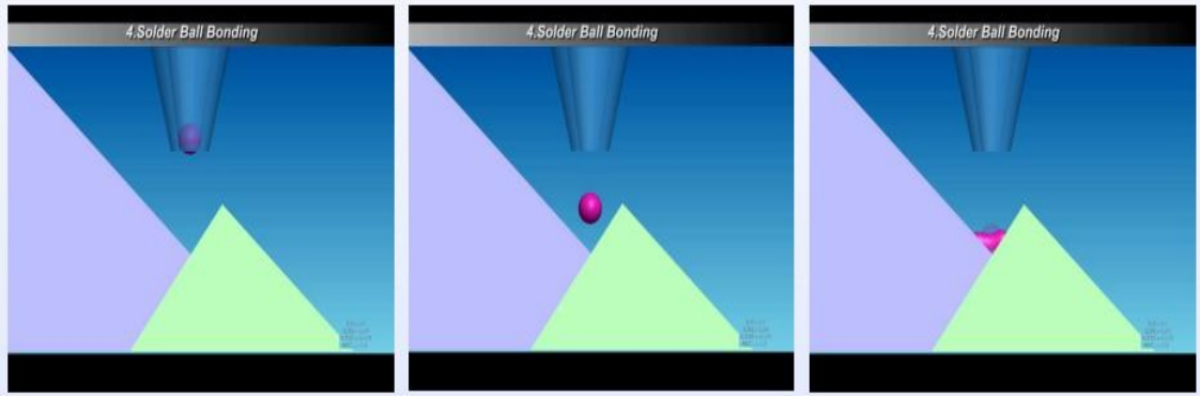

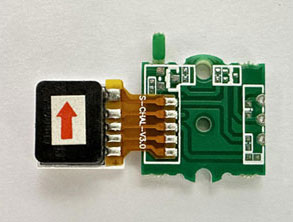

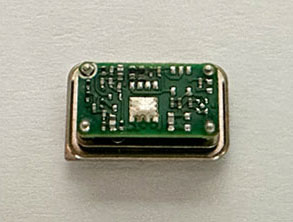

principle of laser solder ball welding module

principle:

the tin balls are divided into one by mechanical movement and transported to the welding nozzle one by one. The tin balls are melted by laser irradiation and sprayed onto the weldment under the action of pressure. Since the position of the tin ball and the parameters in the welding nozzle are monitored in real time by the detection mechanism, the starting spraying time of the laser emitter can be accurately controlled, so the welding with high precision and high accuracy can be achieved.

process:

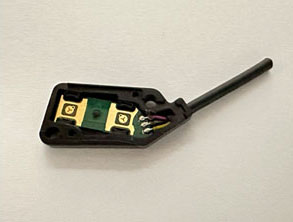

- • Add the tin ball into the tin ball cavity, divide the ball, and separate the tin ball into the guide channel;

- • The solder ball reaches the end of the nozzle through the guide channel, emits laser melting, pressurizes and sprays it onto the pad to complete the welding.

advantages:

- • Non contact type, no damage to the product;

- • Helpless flux, no pollution, Wuxi bead residue;

- • Efficient and fast

Optoelectronic industry

Wire industry

Communications industry

provided by

provides the following services

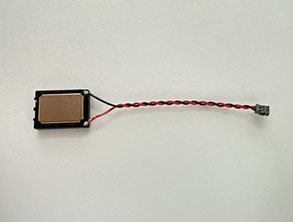

complete welding module

complete machine (platform machine or customized machine)

complete welding head