Single / two component screw valve

The product has the advantages of constant conveying flow, no pulsation and low shear, especially for conveying high viscosity, sensitive and granular media.

Therefore, preeflow is: a solution for a variety of complex applications!

product advantages

true volumetric conveying  endless piston principle @ technology

endless piston principle @ technology

wide applicable viscosity range  applicable to various viscosity media

applicable to various viscosity media

easy to clean  modular design, easy to use and clean

modular design, easy to use and clean

precise volume control  the output flow is directly proportional to the speed and is not affected by the changes of medium viscosity, pressure and temperature

the output flow is directly proportional to the speed and is not affected by the changes of medium viscosity, pressure and temperature

high precision conveying  accurate metering, flow error less than 1%

accurate metering, flow error less than 1%

high repetition accuracy  conveying repetition accuracy above 99%

conveying repetition accuracy above 99%

it can transport medium containing particles  the maximum medium particles can reach 1 mm

the maximum medium particles can reach 1 mm

high speed  up to 3 times / s

up to 3 times / s

versatility  easy integration with automation system and simple control

easy integration with automation system and simple control

no pulsation  stable and stable output flow

stable and stable output flow

stable output  self sealing structure design

self sealing structure design

it can be sucked back  no drip, no wire drawing

no drip, no wire drawing

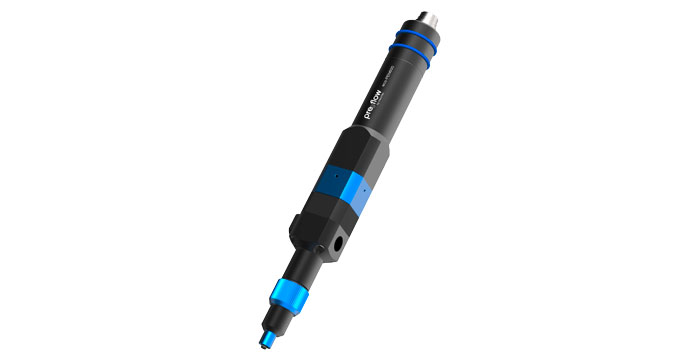

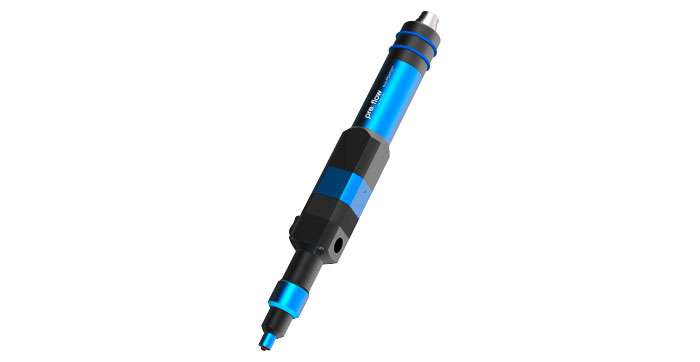

single component screw valve

eco-PEN300

Minimum delivery: 0.001 ml

Adjustable flow range: 0.12 – 1.48 ml/min

Weight: 280 G

eco-PEN330

Minimum delivery: 0.002 ml

Adjustable flow range: 0.2 & ndash; 3.3 ml/min

Weight: 300 g

eco-PEN450

Minimum delivery: 0.004 ml

Adjustable flow range: 0.50 & ndash; 6.00 ml/min

Weight: 300 g

eco-PEN600

Minimum delivery: 0.015 ml

Adjustable flow range: 1.40 & ndash; 16.0 ml/min

Weight: 650 g

eco-PEN700

Minimum conveying capacity: 0.060ml

Adjustable flow range: 5.3-60.0ml/min

Weight: 750 g

eco-PEN700-3D

Minimum delivery: 0.060 ml

Adjustable flow range: 5.30 – 60.0 ml/min

Weight: 650 g

two component screw valve

eco-DUO330

Minimum delivery: 0.005 ml

Adjustable flow range: 0.1 bis 6.6 ml / min

Weight: 1.230g

eco-DUO450

Minimum conveying capacity: 0.010ml

Adjustable flow range: 0.2 bis 12 ml / min

Weight: 1.230g

eco-DUO600

Minimum conveying capacity: 0.030ml

Adjustable flow range: 0.6 bis 32 ml / min

Weight: 1.880g

control unit

eco-CONTROL DUO

Two component desktop controller

Length x width x height: 240x110x210 mm

eco-CONTROL EC200-B

Universal controller

L x W x H: 197x88x240 mm

eco-CONTROL EC200-K

Single component desktop controller

L x W x H: 240x 100x260 mm

Plug‘ n’ Dose

Simple controller

L x W x H: 142x85x50 mm

industry application

Photovoltaic solar energy industry

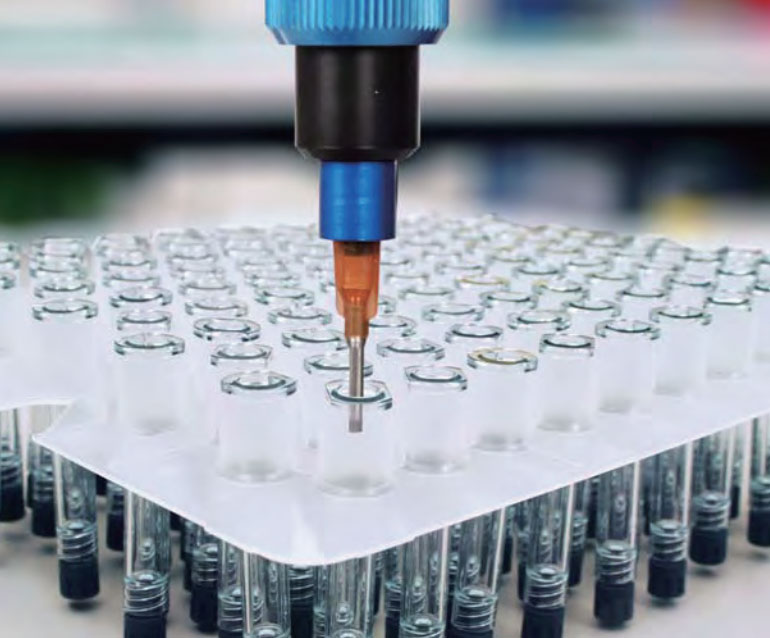

Medical industry

Optical and optoelectronic industry

SMD/SMT

Electronic components industry

Laboratory

Semiconductor manufacturing industry

LED/LED

Biological / chemical industry

And more

| description | eco-PEN300 |

| product number | 20505 |

| external dimensions | length 216 mm, Ø 33 mm |

| weight | 280 g |

| working pressure | 0-6 bar |

| maximum delivery pressure (1) | 20 bar |

| viscosity | water to pasty |

| volumetric flow | 0.12 – 1.48 ml/min |

| minimum dosage | 0.001 ml |

| conveying accuracy (2) | ± 1 % |

| stator material | VisChem |

| material inlet | G 1/8“ DIN/ISO 228 |

| material outlet | luer lock patented technology (patented) |

| parts in contact with materials | POM / stainless steel / VisChem / HD-PE |

| operating temperature | 10-40℃ |

| repeat accuracy | >99 % |

| description | eco-PEN330 |

| product number | 21525 |

| external dimensions | length 225 mm, Ø 33 mm |

| weight | 300 g |

| working pressure | 0-6 bar |

| maximum delivery pressure (1) | 20 bar |

| viscosity | aqueous to mushy |

| volumetric flow | 0.2 – 3.3 ml/min |

| minimum dosage | 0.002 ml |

| conveying accuracy (2) | ± 1 % |

| stator material | VisChem (optional VisLas) |

| material inlet | G 1/8“ DIN/ISO 228 |

| material outlet | luer lock patented technology lpatented) |

| parts in contact with materials | POM / stainless steel / VisChem / HD-PE |

| operating temperature | 10-40℃ |

| repeat accuracy | >99 % |

| description | eco-PEN450 |

| product number | 20092 |

| external dimensions | length 228 mm, Ø 33 mm |

| weight | 300g |

| working pressure | 0-6 bar |

| maximum delivery pressure (1) | 20 bar |

| viscosity | aqueous to mushy |

| volumetric flow | 0.5-6.0 ml/min |

| minimum dosage | 0.004 ml |

| conveying accuracy (2) | ± 1% |

| stator material | VisChem (optional VisLas) |

| material inlet | G 1/8“ DIN/ISO 228 |

| material outlet | luer lock patented technology lpatented) |

| parts in contact with materials | POM / stainless steel / VisChem / HD-PE |

| operating temperature | 10-40° ℃ |

| repeat accuracy | > 99 % |

| description | eco-PEN600 |

| product number | 20048 |

| external dimensions | length 274 mm, Ø 40 mm |

| weight | 650g |

| working pressure | 0-6 bar |

| maximum delivery pressure (1) | 20 bar |

| viscosity | aqueous to mushy |

| volumetric flow | 1.4-16.0 ml/min |

| minimum dosage | 0.015 ml |

| conveying accuracy (2) | ± 1% |

| stator material | VisChem (optional VisLas) |

| material inlet | G 1/4“ DIN/ISO 228 |

| material outlet | luer lock patented technology lpatented) |

| parts in contact with materials | POM / stainless steel / VisChem / HD-PE |

| operating temperature | 10-40° ℃ |

| repeat accuracy | >99 % |

| description | eco-PEN700 |

| product number | 20723 |

| external dimensions | length 274 mm, Ø 40 mm |

| weight | 750 g |

| working pressure | o-6 bar |

| maximum delivery pressure (1) | 10 bar |

| viscosity | aqueous to mushy |

| volumetric flow | 5.3-60.0ml/min |

| minimum dosage | 0.060 ml |

| conveying accuracy (2) | ± 1% |

| stator material | VisChem |

| material inlet | G 1/4“ DIN/ISO 228 |

| material outlet | luer lock patented technology (patented) |

| parts in contact with materials | POM / stainless steel / VisChem / HD-PE |

| operating temperature | 10-40℃ |

| repeat accuracy | >99 % |

| description | eco-PEN700-3D |

| product number | 20723 |

| external dimensions | length 274 mm, Ø 40 mm |

| weight | 650g |

| working pressure | o-6 bar |

| maximum delivery pressure (1) | 10 bar |

| viscosity | aqueous to mushy |

| volumetric flow | 5.3-60.0 ml/min |

| minimum dosage | 0.060 ml[9 |

industry application

Photovoltaic solar energy industry

Medical industry

Optical and optoelectronic industry

SMD/SMT

Electronic components industry

Laboratory

Semiconductor manufacturing industry

LED/LED

Biological / chemical industry

And more

| description | eco-PEN300 |

| product number | 20505 |

| external dimensions | length 216 mm, Ø 33 mm |

| weight | 280 g |

| working pressure | 0-6 bar |

| maximum delivery pressure (1) | 20 bar |

| viscosity | water to pasty |

| volumetric flow | 0.12 – 1.48 ml/min |

| minimum dosage | 0.001 ml |

| conveying accuracy (2) | ± 1 % |

| stator material | VisChem |

| material inlet | G 1/8“ DIN/ISO 228 |

| material outlet | luer lock patented technology (patented) |

| parts in contact with materials | POM / stainless steel / VisChem / HD-PE |

| operating temperature | 10-40℃ |

| repeat accuracy | >99 % |

| description | eco-PEN330 |

| product number | 21525 |

| external dimensions | length 225 mm, Ø 33 mm |

| weight | 300 g |

| working pressure | 0-6 bar |

| maximum delivery pressure (1) | 20 bar |

| viscosity | aqueous to mushy |

| volumetric flow | 0.2 – 3.3 ml/min |

| minimum dosage | 0.002 ml |

| conveying accuracy (2) | ± 1 % |

| stator material | VisChem (optional VisLas) |

| material inlet | G 1/8“ DIN/ISO 228 |

| material outlet | luer lock patented technology lpatented) |

| parts in contact with materials | POM / stainless steel / VisChem / HD-PE |

| operating temperature | 10-40℃ |

| repeat accuracy | >99 % |

| description | eco-PEN450 |

| product number | 20092 |

| external dimensions | length 228 mm, Ø 33 mm |

| weight | 300g |

| working pressure | 0-6 bar |

| maximum delivery pressure (1) | 20 bar |

| viscosity | aqueous to mushy |

| volumetric flow | 0.5-6.0 ml/min |

| minimum dosage | 0.004 ml |

| conveying accuracy (2) | ± 1% |

| stator material | VisChem (optional VisLas) |

| material inlet | G 1/8“ DIN/ISO 228 |

| material outlet | luer lock patented technology lpatented) |

| parts in contact with materials | POM / stainless steel / VisChem / HD-PE |

| operating temperature | 10-40° ℃ |

| repeat accuracy | > 99 % |

| Description | eco-PEN600 |

| Product number | 20048 |

| Appearance dimension | Length 274 mm, Ø 40 mm |

| Weight | 650g |

| Working pressure | 0-6 bar |

| Maximum delivery pressure (1) | 20 bar |

| Viscosity | Aqueous to mushy |

| Volumetric flow | 1.4-16.0 ml/min |

| Minimum dosage | 0.015 ml |

| Conveying accuracy (2) | ± 1% |

| Stator material | VisChem (optional VisLas) |

| Material inlet | G 1/4“ DIN/ISO 228 |

| Material outlet | Luer lock patented technology lpatented) |

| Parts in contact with materials | POM / stainless steel / VisChem / HD-PE |

| Operating temperature | 10-40° ℃ |

| Repetition accuracy | >99 % |

| Description | eco-PEN700 |

| Product number | 20723 |

| Appearance dimension | Length 274 mm, Ø 40 mm |

| Weight | 750 g |

| Working pressure | o-6 bar |

| Maximum delivery pressure (1) | 10 bar |

| Viscosity | Aqueous to mushy |

| Volumetric flow | 5.3-60.0ml/min |

| Minimum dosage | 0.060 ml |

| Conveying accuracy (2) | ± 1% |

| Stator material | VisChem |

| Material inlet | G 1/4“ DIN/ISO 228 |

| Material outlet | Luer lock patented technology (patented) |

| Parts in contact with materials | POM / stainless steel / VisChem / HD-PE |

| Operating temperature | 10-40℃ |

| Repetition accuracy | >99 % |

| Description | eco-PEN700-3D |

| Product number | 20723 |

| Appearance dimension | Length 274 mm, Ø 40 mm |

| Weight | 650g |

| Working pressure | o-6 bar |

| Maximum delivery pressure (1) | 10 bar |

| Viscosity | Aqueous to mushy |

| Volumetric flow | 5.3-60.0 ml/min |

| Minimum dosage | 0.060 ml |

| Conveying accuracy (2) | ± 1% |

| Stator material | VisChem |

| Material inlet | G 1/4“ DIN/ISO 228 |

| Material outlet | Luer lock patented technology (patented) |

| Parts in contact with materials | POM / stainless steel / VisChem / HD-PE |

| Operating temperature | 10-40℃ |

| Repetition accuracy | >99 % |

| Description | eco-DUO330 |

| Product number | 21529 |

| Description | 228 mmx163 mm |

| Weight | 1230g |

| Working pressure | 0-20 bar |

| Maximum delivery pressure (1) (4) | 40 bar |

| Viscosity | Water to pasty |

| Volumetric flow (3) | 0.1 – 6.6 ml/min (at 1:1) |

| Minimum dosage | 0.005 ml |

| Conveying accuracy (2) | ± 1% |

| Mixing ratio | 1:1-10:1 |

| Stator material | VisChem (optional VisLas) |

| Material inlet | G 1/8" DIN/ISO 228 |

| Material outlet | static mixer, bayonet lock |

| Parts in contact with materials | Aluminium, anodized / POM / stainless steel/ VisChem / HD-PE(optional VisLas) |

| Operating temperature | 10-40°℃ |

| Repetition accuracy | >99 % |

| Description | eco-DUO450 |

| Product number | 20639 |

| Description | 228 mm x 163 mm |

| Weight | 1230g |

| Working pressure | 0-20 bar |

| Maximum delivery pressure (1) (4) | 40 bar |

| Viscosity | Water to pasty |

| Volumetric flow (3) | 0.2-12 ml/min (at 1:l) |

| Minimum dosage | 0.010 ml |

| Conveying accuracy (2) | 1% |

| Mixing ratio | 1:1-10:1 |

| Stator material | VisChem (optional VisLas) |

| Material inlet | G 1/8“ DIN/ISO 228 |

| Material outlet | static mixer, bayonet lock |

| Parts in contact with materials | Aluminium, anodized / POM / stainless steel / VisChem / HD-PE (optional VisLas) |

| Operating temperature | 10-40℃ |

| Repetition accuracy | >99% |

| Description | eco-DUO600 |

| Product number | 21175 |

| Description | 301 mm x 163 mm |

| Weight | 1880g |

| Working pressure | 0-20 bar |

| Maximum delivery pressure (1) (4) | 40 bar |

| Viscosity | Water to pasty |

| Volumetric flow (3) | 0.6-32.0 ml/min (at 1:1) |

| Minimum dosage | 0.030 ml |

| Conveying accuracy (2) | ± 1 % |

| Mixing ratio | 1:1-10:1 |

| Stator material | VisChem (optional VisLas) |

| Material inlet | G 1/4“ DIN/ISO 228 |

| Material outlet | static mixer, bayonet lock |

| Parts in contact with materials | Aluminium, anodized / POM / stainless steel / VisChem/ HD-PE(optional VisLas) |

| Operating temperature | 10-40° ℃ |

| Repetition accuracy | >99% |